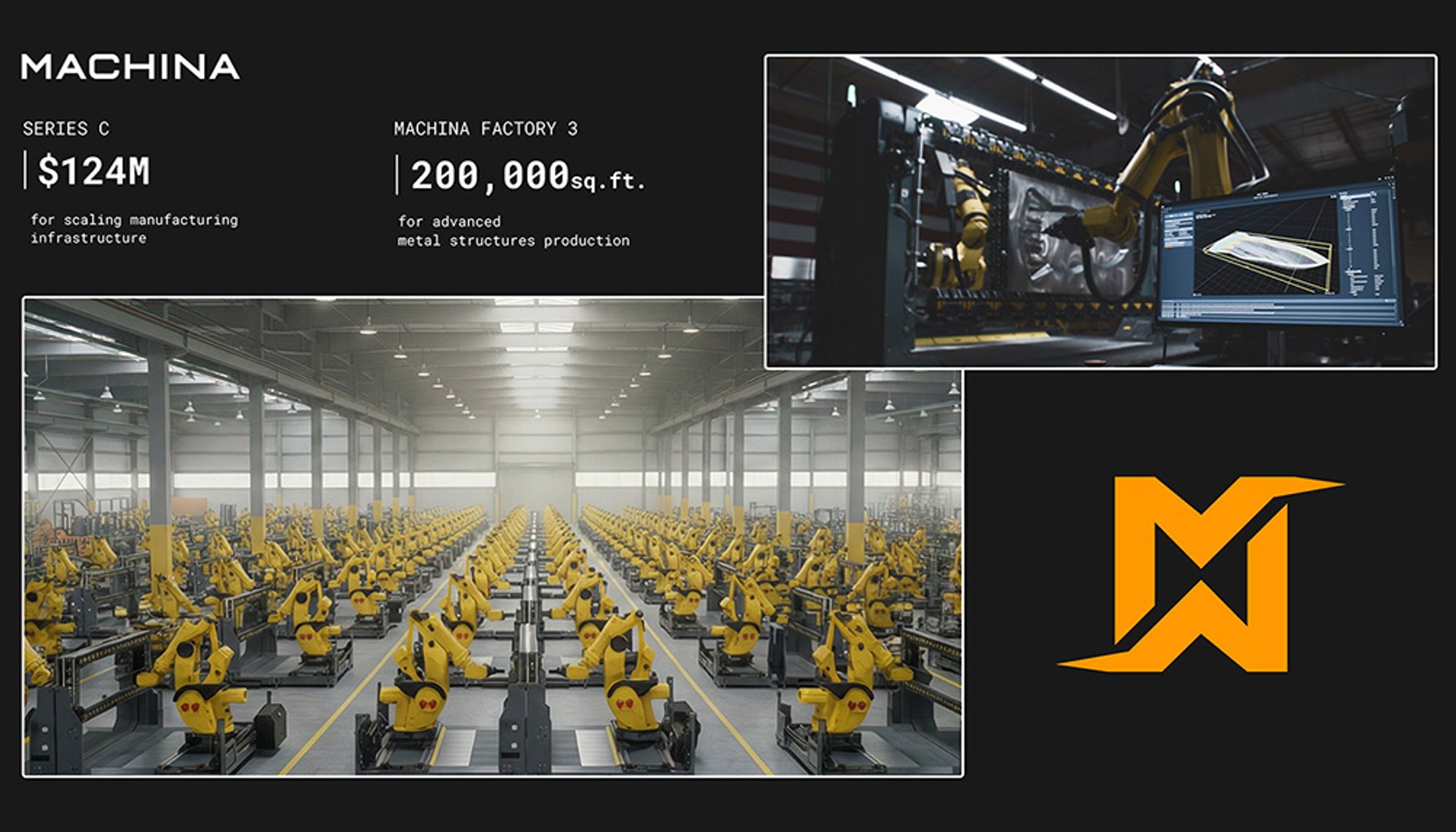

$124 Million to Reprogram Factories: Machina Labs Launches Smart Facility

By Maxine Shaw

Image / www.therobotreport.com

Machina Labs just secured a $124 million lifeline—and it's not just for show. This funding is set to turbocharge the deployment of factories that can actually keep pace with the demands of modern manufacturing.

The Los Angeles-based startup, founded in 2019, has unveiled its first large-scale intelligent factory, leveraging its RoboCraftsman platform to transform digital designs into production-grade metal parts. Edward Mehr, co-founder and CEO, emphasized the urgency: “The world’s most advanced designs are being held back by 20th-century factories.” In an industry where speed and efficiency are paramount, the call for a reimagined manufacturing infrastructure is deafening.

Integration teams report that traditional manufacturing methods are often bogged down by outdated processes, resulting in slow turnaround times and excessive costs. Machina Labs aims to eliminate these bottlenecks by enabling factories that can adapt and respond to changing production needs rapidly. The RoboCraftsman integrates advanced robotics with AI-driven process controls, which means that manufacturers can expect cycle time improvements that were previously unthinkable.

For instance, Machina Labs' technology is expected to cut production times for complex metal components from weeks to just days. This is particularly critical for sectors such as aerospace and defense, where the need for rapid prototyping and quick deployment is essential. Production data shows that factories utilizing similar adaptive technologies have seen throughput improvements of as much as 50%, dramatically shortening the lead time for critical components.

Funding from key players, including Woven Capital (Toyota’s venture arm) and Lockheed Martin Ventures, underscores the potential ROI for these advancements. Investors are banking on Machina Labs' promise of a smart factory that can respond to the demands of modern manufacturers without the typical hidden costs often associated with new tech deployments.

However, not all the glitz of “seamless integration” comes without challenges. Integration requirements can be significant, with floor space and power needs potentially doubling for advanced robotic systems compared to traditional setups. Furthermore, the training hours required for existing staff to operate and maintain these new systems should not be underestimated. Floor supervisors confirm that even with cutting-edge technology, human oversight remains indispensable. Certain tasks, especially those requiring intricate assembly or quality checks, still need skilled workers to ensure precision and quality control.

Machina Labs’ approach is not without its skeptics. Industry veterans often question the feasibility of fully automating complex manufacturing processes. The reality is that while AI and robotics can substantially improve efficiency, they cannot entirely replace the nuanced decision-making skills and craftsmanship that human workers bring to the table.

As Machina Labs moves forward, the key will be in balancing automation with human expertise. The payback period for such investments, based on historical data from similar deployments, could range from 12 to 18 months, but only if the integration challenges are effectively managed. If not, companies may find themselves facing unanticipated costs that could derail their financial projections.

In an industry that has long been resistant to change, Machina Labs' $124 million bet represents a pivotal shift toward a future where manufacturing is not just faster, but smarter. As the factory of the future begins to take shape, the question remains: will it truly be able to meet the expectations set by its ambitious backers?

Sources

Newsletter

The Robotics Briefing

Weekly intelligence on automation, regulation, and investment trends - crafted for operators, researchers, and policy leaders.

No spam. Unsubscribe anytime. Read our privacy policy for details.