AstraZeneca Bets Big on Robotic Automation for Cell Therapy

By Maxine Shaw

Multiply Labs is set to revolutionize cell therapy manufacturing, and AstraZeneca is placing its bets on this collaboration. The pharmaceutical giant has partnered with the autonomous manufacturing specialist to explore the deployment of GMP (Good Manufacturing Practices)-ready robotic systems aimed at enhancing production efficiency.

This initiative comes at a crucial time when the demand for cell therapies is skyrocketing, yet the manufacturing processes remain labor-intensive and prone to variability. The potential benefits of this partnership are staggering: industry insiders report that automating cell therapy production could lead to a 30% reduction in cycle time, drastically improving throughput and lowering costs.

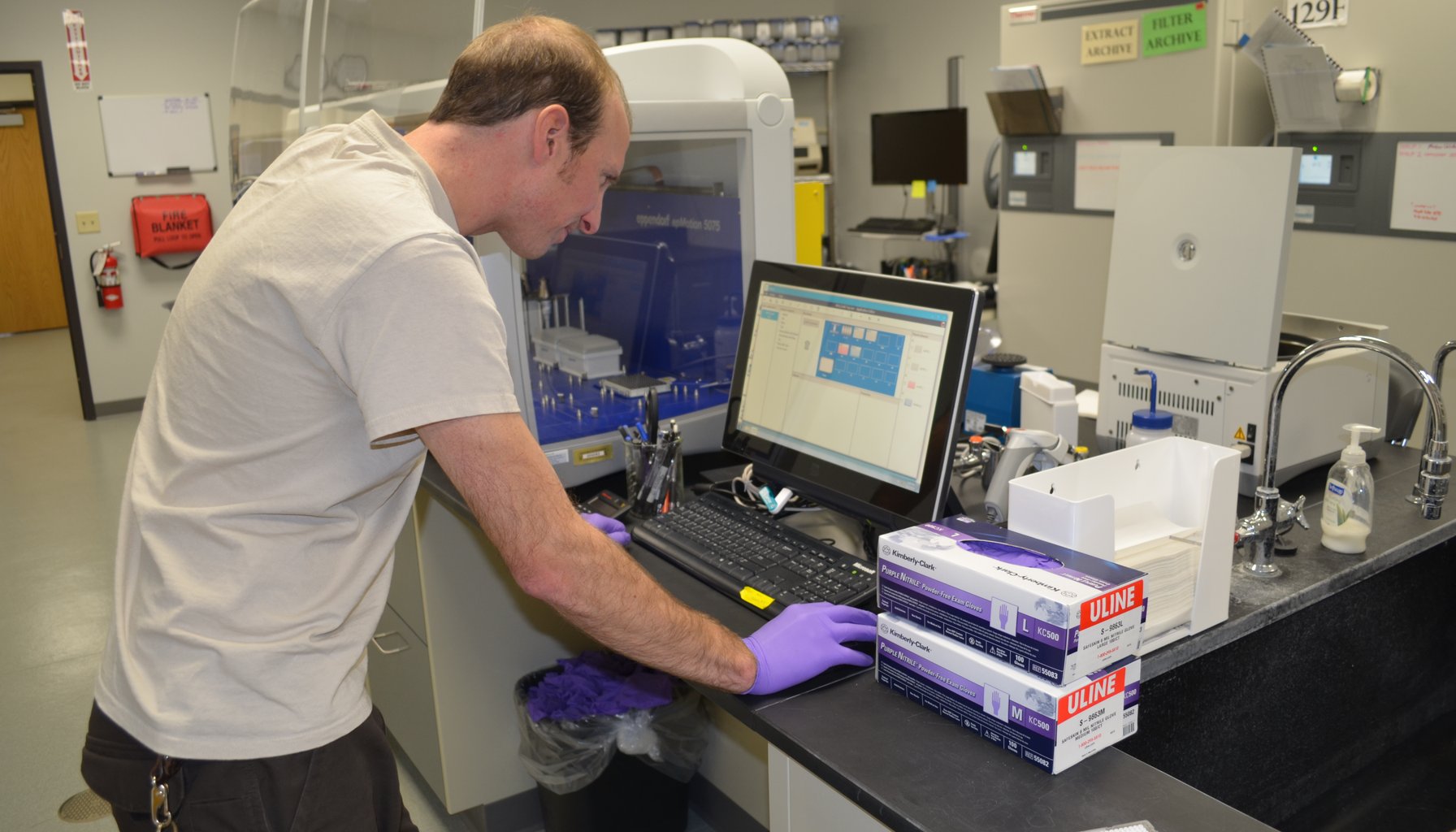

A primary focus of this collaboration will be the end-to-end robotic automation of standard instruments used in the intricate production of cell therapies. Multiply Labs is known for its expertise in autonomous manufacturing, and its technology promises to streamline processes that currently require significant manual intervention. The integration of robotics not only aims to enhance consistency but also to eliminate human error, which has historically plagued the sector.

However, implementing such systems is not without its challenges. The integration teams will need to navigate complex regulatory landscapes and ensure that all robotic processes comply with GMP standards. Floor space and power requirements for these systems must also be carefully assessed; analysts estimate that a shift to fully automated cell therapy manufacturing could necessitate an additional 15-20% more floor space in existing facilities.

Moreover, while automation can handle the bulk of repetitive tasks, certain aspects of cell therapy production will still require skilled human workers. Tasks involving critical decision-making, such as quality control and troubleshooting, cannot be easily automated. Thus, it's vital for companies like AstraZeneca to not only invest in technology but also in the training of their workforce to manage and maintain these sophisticated systems.

The financial implications of this partnership are considerable. AstraZeneca is likely to see a return on investment (ROI) that could be realized in as little as 12 to 18 months post-deployment, depending on the scale of integration and the specific technologies employed. This is crucial for CFOs evaluating capital expenditures, as the initial costs of robotic systems can be daunting. Vendors often tout seamless integration, but the reality may involve unexpected hidden costs—such as additional training hours and maintenance—adding up to an extra $50,000 to the budget.

As cell therapy continues to evolve, the need for scalable and efficient manufacturing solutions will only grow. AstraZeneca’s collaboration with Multiply Labs is a clear acknowledgment of this reality. If successful, this combination of pharmaceutical expertise and cutting-edge automation technology may well set a new standard for the industry.

In the coming months, industry watchers will be keen to see how this partnership unfolds and what operational metrics emerge from the deployment. Will Multiply Labs be able to deliver on its promises of efficiency and quality? Only time will tell, but one thing is clear: the stakes are high, and the potential rewards are immense.

Sources

Newsletter

The Robotics Briefing

Weekly intelligence on automation, regulation, and investment trends - crafted for operators, researchers, and policy leaders.

No spam. Unsubscribe anytime. Read our privacy policy for details.