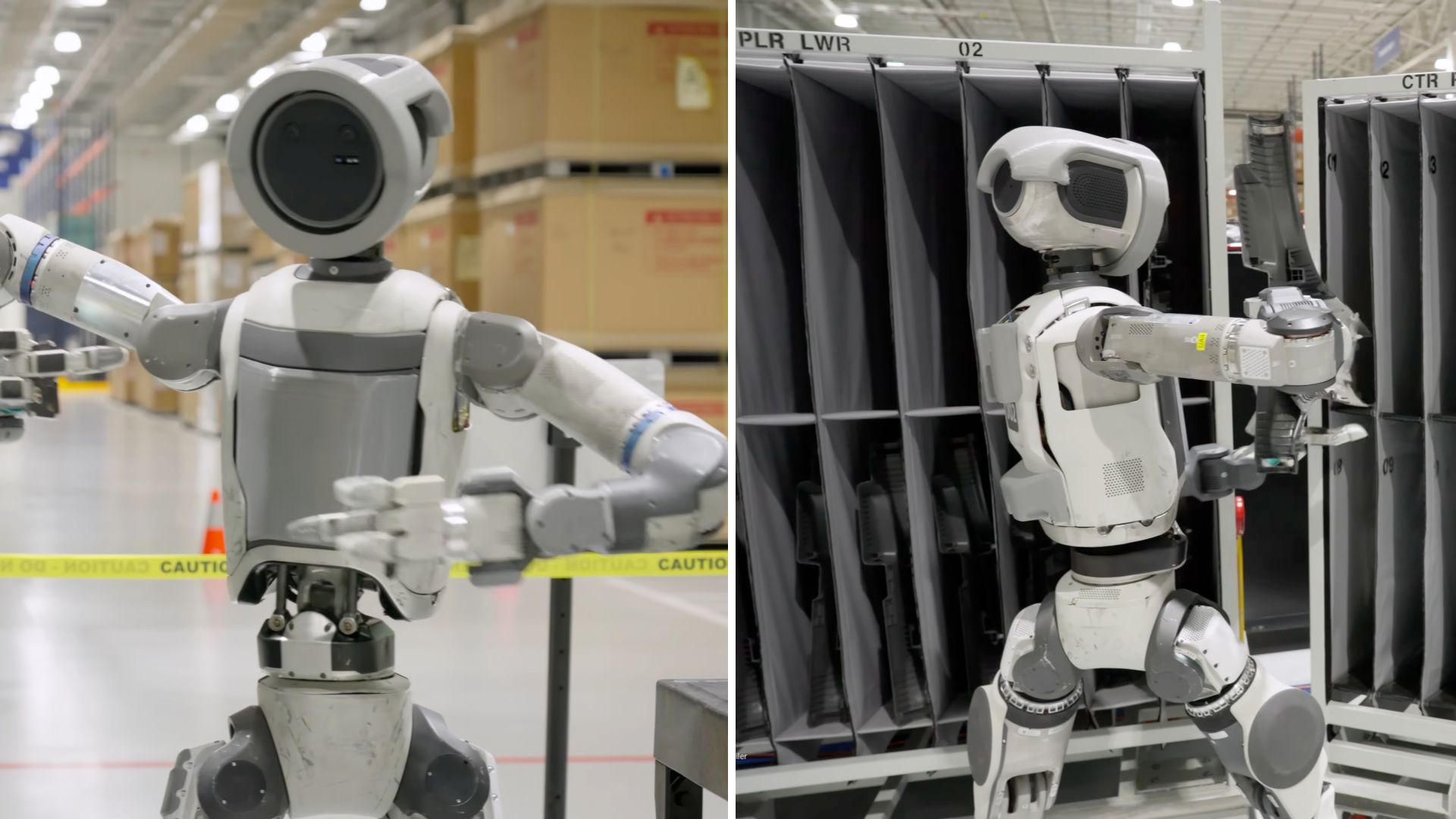

Atlas Humanoid Robot Takes on Real Factory Tasks at Hyundai Plant

By Maxine Shaw

Production data from [facility] shows boston Dynamics' humanoid robot Atlas recently made headlines as it entered Hyundai's new plant near Savannah, Georgia, performing tasks that could redefine labor on the factory floor. With advanced AI capabilities and groundbreaking design, Atlas showcases the future of manufacturing like never before.

The emergence of Atlas marks a significant turning point in robotics, moving from laboratory development to real-world applications. As industries seek to enhance productivity and reduce labor costs, Atlas is positioned to play a critical role in automating complex tasks, potentially transforming factory operations. Hyundai's investment in deploying tens of thousands of these robots underscores the urgency for businesses to adapt to the evolving landscape of industrial automation.

Atlas: A New Kind of Worker

Standing at 5 feet 9 inches and weighing 200 pounds, Atlas is engineered to perform tasks previously deemed too complex for robots. Its advanced joint design enables complete rotations without the encumbrance of wires, providing unprecedented agility. During a demonstration on CBS's 60 Minutes, Atlas sorted roof racks and tackled tasks that challenged its dexterity. (WATCH: Boston Dynamics Atlas humanoid robot masters tough factory jobs)

Economic Impacts and Industry Prospects

"We've pushed robotics beyond merely mimicking human actions," said Robert Playter, CEO of Boston Dynamics. "We want robots to excel at tasks that are too laborious or dangerous for humans." As Atlas engages in sorting and other specific tasks, it relies on teleoperation training to gather the necessary data for autonomous operation.

Challenges in Adoption

The market for humanoid robots like Atlas is projected to reach $38 billion by 2035, signaling a notable shift in investment and focus within the robotics sector. In 2025 alone, $4.6 billion was allocated to humanoid robotics development, reflecting a rising trend in demand for more advanced automation solutions. (WATCH: Boston Dynamics Atlas humanoid robot masters tough factory jobs)

Hyundai's plans for Atlas include the acquisition of tens of thousands of units as part of their production strategy. This deployment promises to impact labor dynamics within manufacturing, as Atlas takes on roles traditionally filled by human workers. Heung-soo Kim, head of global strategy at Hyundai, remarked, "This is just the start of a great journey."

Constraints and tradeoffs

- Integration with existing workflows is essential but complex.

- The need for operator oversight during initial deployments can slow the process.

- Current safety protocols may require adaptation for humanoid robots.

Verdict

Atlas shows promise in enhancing factory productivity, but reliability and cost remain key obstacles before widespread adoption.

Challenges in Adoption