NORD Unveils Digital Twin for Robotic Drives

By Sophia Chen

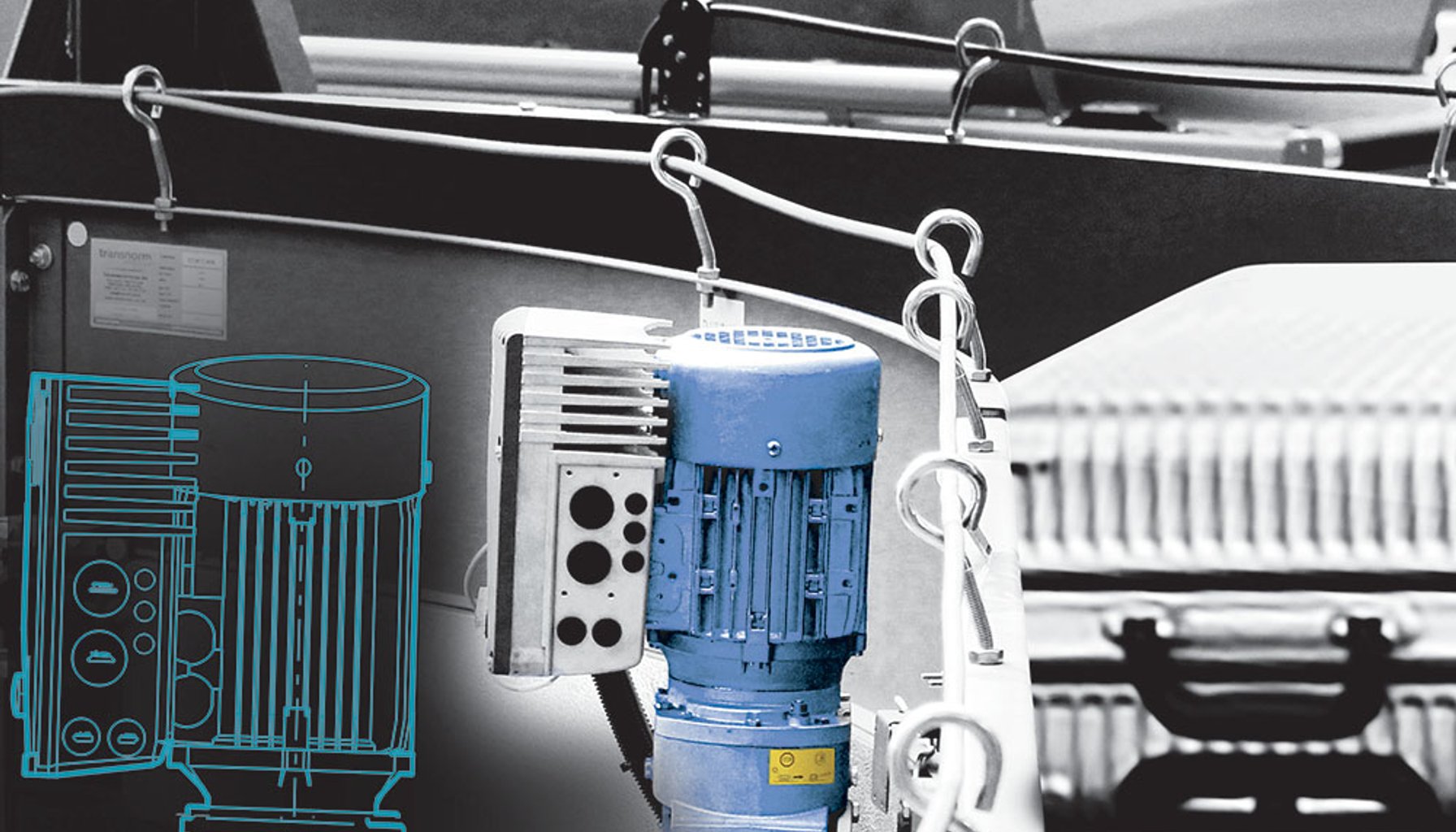

Image / therobotreport.com

Virtual commissioning could shave weeks off complex robot projects.

NORD Drivesystems has launched a digital twin platform aimed at robotic developers, letting engineers test drive concepts in a virtual world before any hardware is built. Engineering documentation shows the twins are generated from a customer’s myNORD configuration, turning a real drive system into a ready-to-simulate model. The promise is straightforward: verify drive concepts early and compress planning cycles through virtual commissioning, a workflow that has gained traction in automation since the FMI standard gained traction more than a decade ago.

The platform’s pitch isn’t just “more software” for squeaky prototypes. It rests on two core ideas: first, that co-simulation of drives and control logic can catch integration issues sooner; second, that data-driven simulations, not just CAD faith, can tune performance for the given application. NORD emphasizes that the twins support planning and concept validation across its portfolio—standard drives, energy-saving variants, explosion-protected configurations, and application-specific concepts—via a digital service that scales with project complexity. In other words, you can test “the robot’s drivetrain” in a controlled virtual environment before committing to a physical build.

NORD is a German firm with about 4,700 employees, and this move sits squarely in its longer software-and-systems strategy. The company notes the twins support virtual commissioning, which can significantly reduce project time for even complex drive systems. The drive manufacturer’s pedigree—rooted in rugged, safety-conscious solutions—adds credibility for robotics developers who must meet strict reliability and safety standards in real-world environments. The platform is tied to the myNORD configuration ecosystem, underscoring a shift from purely mechanical engineering toward end-to-end digital integration.

From a practitioner’s standpoint, the move reflects a growing industry pattern: the best way to derisk robo-mechanisms with lots of dynamic interaction (torque, backlash, and load variability) is to model them as accurately as possible in software before touching metal. The FMI standard’s reuse-friendly ethos makes it easier to swap models in and out as control strategies evolve, something engineers will care about as they experiment with advanced actuation schemes and safety interlocks in humanoid-inspired drives. The data-centric angle also hints at closer ties between procurement, simulation, and manufacturing—potentially shortening lead times for customized, region-specific drive trains.

Assessment and insights for decision-makers

Overall, NORD’s digital twin approach is a meaningful step toward making robot drivetrain development more deterministic and shorter in cycle time—an incremental but real win for teams that have learned to mistrust demo reels more than data.

Sources

Newsletter

The Robotics Briefing

Weekly intelligence on automation, regulation, and investment trends - crafted for operators, researchers, and policy leaders.

No spam. Unsubscribe anytime. Read our privacy policy for details.