OnRobot's Dallas Event: A Response to Labor Crisis

By Maxine Shaw

Image / roboticsandautomationnews.com

“Finding welders is impossible.” That stark reality has driven manufacturers in North Texas to seek automation solutions, and OnRobot is ready to help. On February 19, the company will host the “Build your Automation Roadmap” event in Dallas, tackling the pressing labor shortages that have plagued the region's manufacturing sector.

With a growing demand for skilled labor, companies are facing a dilemma: how to maintain productivity without a sufficient workforce. Production data shows that many manufacturers have seen their output stagnate due to hiring challenges. In fact, the fabrication and machining industries have reported a 30% drop in available skilled workers over the past five years, creating a significant bottleneck in operations.

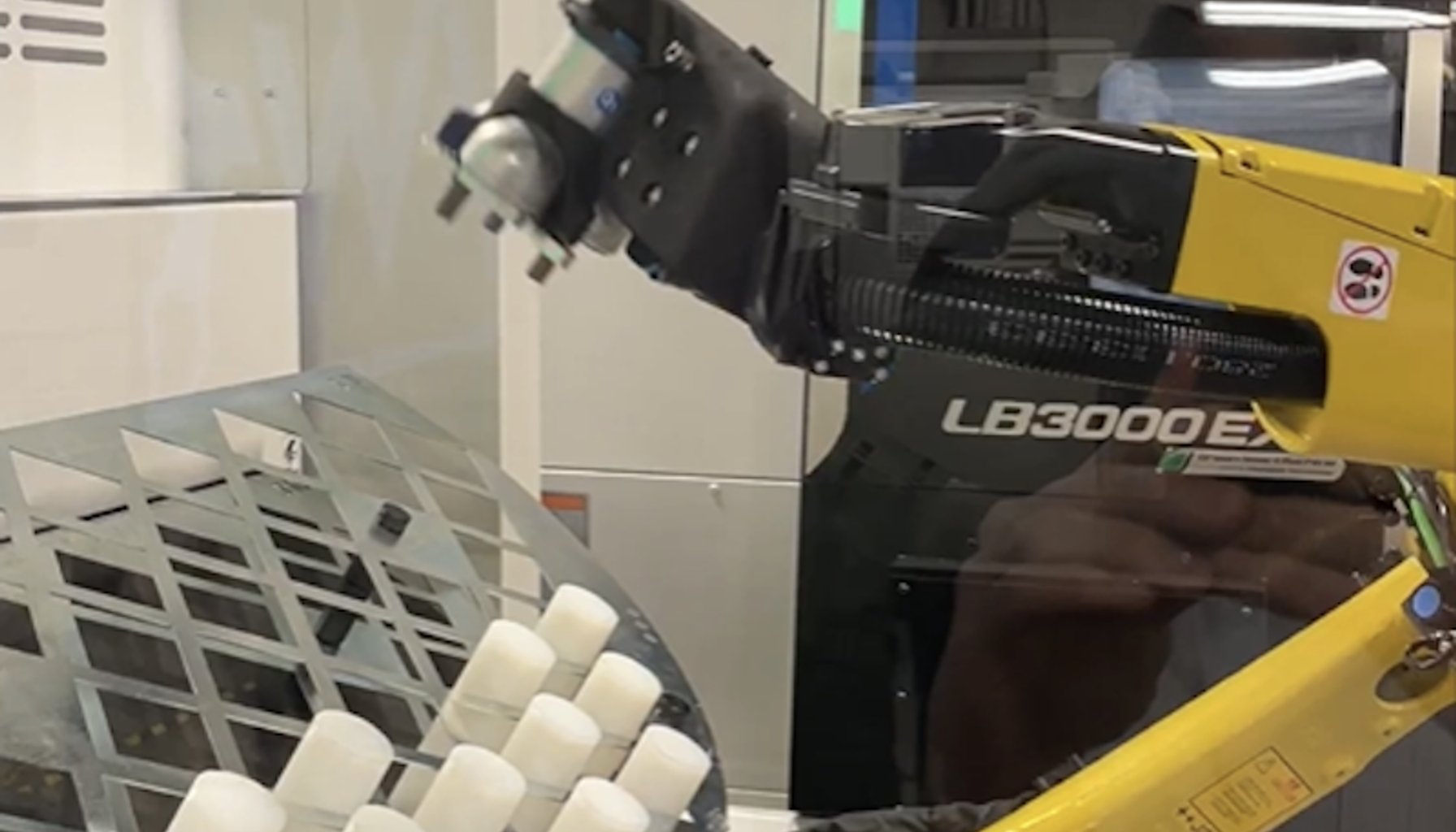

OnRobot’s initiative comes at a critical time. The event promises to deliver practical automation solutions tailored for various sectors, including metal fabrication, CNC machining, electronics, aerospace, and food production. This is not merely a sales pitch; it’s a strategic move to bridge the gap between existing workforce limitations and the increasing demands of modern manufacturing.

The event will feature workshops, case studies, and hands-on demonstrations, providing insights into how automation can enhance operational efficiency and reduce reliance on human labor. For instance, companies that have successfully integrated collaborative robots—cobots—into their production lines report cycle time improvements of up to 40% and a payback period as short as 14 months. These metrics can be game-changers for manufacturers looking to justify capital expenditures in a tight labor market.

However, the transition to automation is not without its challenges. Integration teams report that one of the most significant hurdles is the initial upfront investment and the hidden costs that often accompany new technologies. For example, while a cobot may have a list price of $30,000, the total cost of ownership can escalate when factoring in integration requirements such as floor space, power supply upgrades, and essential training hours. Experts recommend that manufacturers allocate at least an additional 20% of the initial investment for these unforeseen expenses.

Moreover, while automation can significantly streamline operations, it’s essential to recognize that certain tasks still require human intervention. Floor supervisors confirm that complex assembly processes, quality control checks, and tasks requiring intricate decision-making cannot yet be fully automated. Manufacturers must strategically identify which operations can be automated without sacrificing quality or safety.

As OnRobot prepares for this event, they are not just promoting their products—they are responding to a critical need in the industry. The conversation around automation is evolving, and this event aims to equip manufacturers with the tools and knowledge to navigate the complexities of implementing these technologies.

In an era where labor shortages are becoming the norm rather than the exception, the takeaway from the Dallas event will be clear: automation is not just an option; it’s becoming a necessity for survival in the competitive manufacturing landscape. Adapting to these changes effectively could mean the difference between thriving and merely surviving in the years to come.

Sources

Newsletter

The Robotics Briefing

Weekly intelligence on automation, regulation, and investment trends - crafted for operators, researchers, and policy leaders.

No spam. Unsubscribe anytime. Read our privacy policy for details.