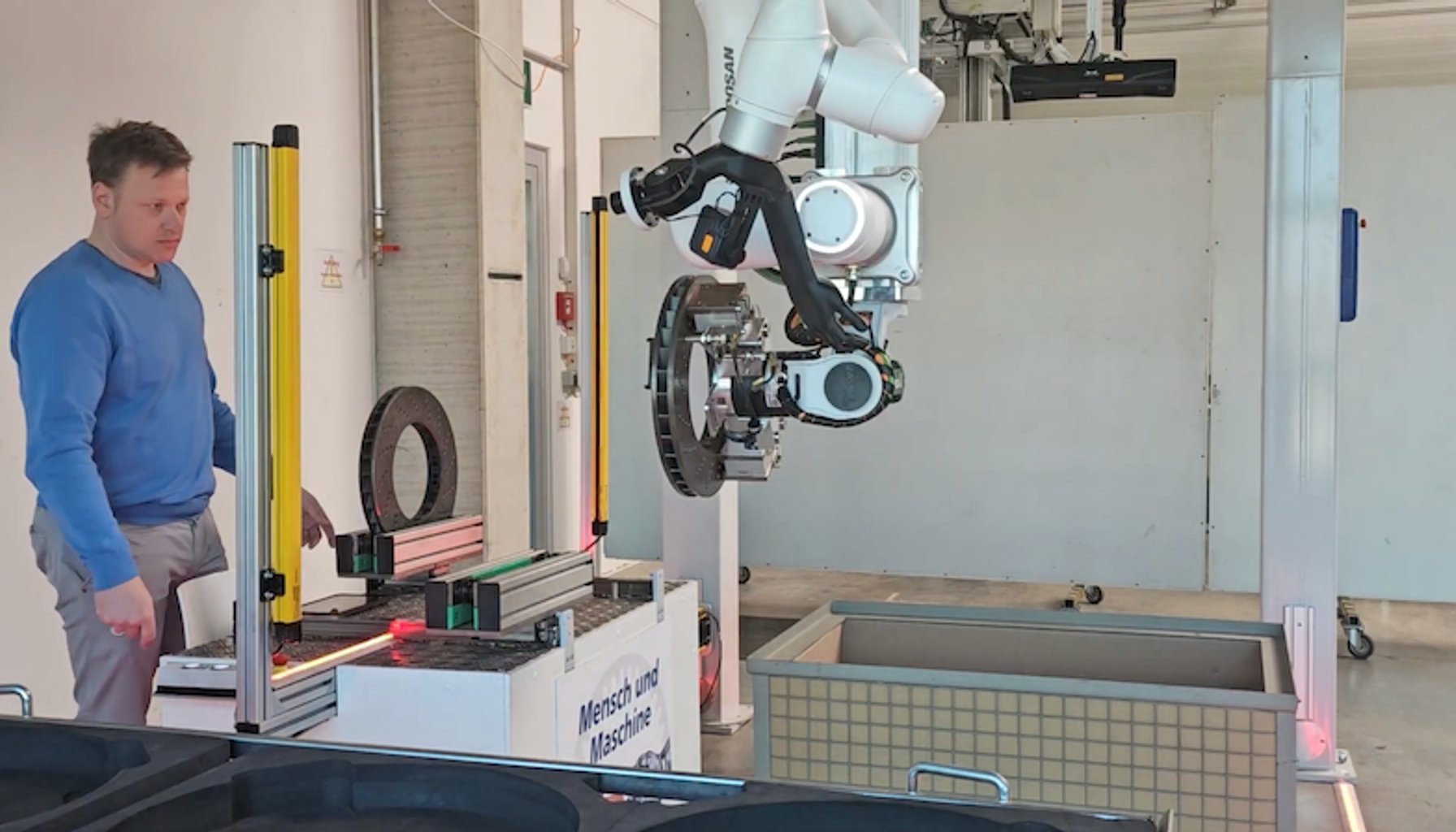

Semi-Automated Bin Picking: The Future of Flexible Manufacturing

By Maxine Shaw

Image / roboticsandautomationnews.com

Manufacturers are caught in a bind: labor shortages are forcing them to rethink their strategies, and the solution might just lie in a middle ground between human skill and intelligent automation.

At Zasche Handling, project engineer Ulrich Schäfer outlines a compelling case for semi-automated bin picking systems that strike this crucial balance. With high-mix production lines becoming the norm, the flexibility offered by these systems could be a game changer. Production data shows that integrating semi-automated bin picking can improve cycle times by up to 30%, a significant leap in efficiency that plant managers cannot ignore.

The reality on the ground is sobering. Companies are grappling with persistent labor shortages that threaten their operational capabilities. According to industry reports, almost 80% of manufacturers say finding skilled workers is their biggest challenge. As a result, many have turned to automation to fill the gaps. However, fully robotic systems often come with a hefty price tag and integration hurdles that can take months, if not years, to overcome. For instance, a fully automated bin picking system can cost upwards of $500,000 and requires specialized training for operators—a barrier that many plants simply cannot afford.

What sets semi-automated systems apart is their ability to complement human workers rather than replace them. Schäfer notes that these systems can handle repetitive tasks while allowing skilled operators to focus on more complex operations. Integration teams report that this arrangement not only boosts throughput but also enhances job satisfaction among workers who can engage in more meaningful tasks. ROI documentation reveals that plants adopting semi-automation see payback periods as short as 12 months, far quicker than their fully automated counterparts.

Yet, the benefits extend beyond mere numbers. Operational metrics show that semi-automated systems have led to fewer workplace injuries. By taking over the most physically demanding tasks, these systems help mitigate fatigue and reduce the risk of injury, which has become a growing concern in the industry. With stricter safety and ergonomic standards in place, companies can’t afford to ignore the human element in their automation strategies.

However, it’s not all smooth sailing. Integration requirements remain a critical consideration. Manufacturers must allocate floor space and power for these systems, and the expectation of training hours should not be underestimated. While semi-automated systems are more user-friendly than fully robotic setups, they still require a learning curve. Floor supervisors confirm that operators need at least 40 hours of training to effectively work alongside these systems.

Moreover, hidden costs can lurk in the shadows. Vendors may tout seamless integration, but the reality often involves unexpected expenses for software updates and maintenance. Manufacturers should be prepared for these scenarios to avoid budget overruns.

In conclusion, the case for semi-automated bin picking is compelling. It addresses the pressing concerns of labor shortages and ergonomic safety while providing a pathway for improved efficiency. As manufacturers continue to navigate the complexities of modern production, this hybrid approach offers a valuable solution that respects both human skills and the capabilities of automation. They are not merely replacing workers; they are enhancing human performance where it counts most.

The numbers don’t lie: with the right planning and execution, semi-automation could very well be the bridge to a more resilient manufacturing future.

Sources

Newsletter

The Robotics Briefing

Weekly intelligence on automation, regulation, and investment trends - crafted for operators, researchers, and policy leaders.

No spam. Unsubscribe anytime. Read our privacy policy for details.